The Agrispread AS120 is a single axle 10.6m³ spreader capable of carrying 10.6 ton of fertiliser or 14.8 ton of lime sand. It easily connects directly to any ISOBUS compatible tractor through the Apollo Virtual Implement which loads into the tractor VT for setup, calibration and rate control. The bin sits on load cells and the variable speed floor belt and spinners are driven hydraulically. The AS120 is durable with the bottom third of the bin and rear spreading deck made from stainless steel. As well all of the fixtures, nuts, bolts and hydraulic fittings are also stainless.

“It’s enabled us to fine-tune our fertilizer right down to the last couple of the kilos in a paddock. So it’s been a big cost-saving there and taking the guesswork out of it.â€â€“ Damien Leeson, Broadacre Farmer Goomalling

AS120 Fertiliser, Lime, Gypsum & Manure Spreader | Standard Specifications

| MODEL | AS120 |

|---|---|

| Capacity1 | 10.6m3 |

| Fertiliser Capacity | 10.6 ton |

| Lime Capacity (Level) | 14.8 ton |

| Tyres | 650/65-30.5 (BKT) |

| Axle | 10 stud |

| Bin Length | 4200 mm |

| Bin Width | 2250 mm |

| Loading Height2 (no loads cells) | 2630 mm |

| Loading Height2 (with loads cells) | 2800 mm |

| Axle Track Width | 2 metre |

| Sprung Drawbar | Yes |

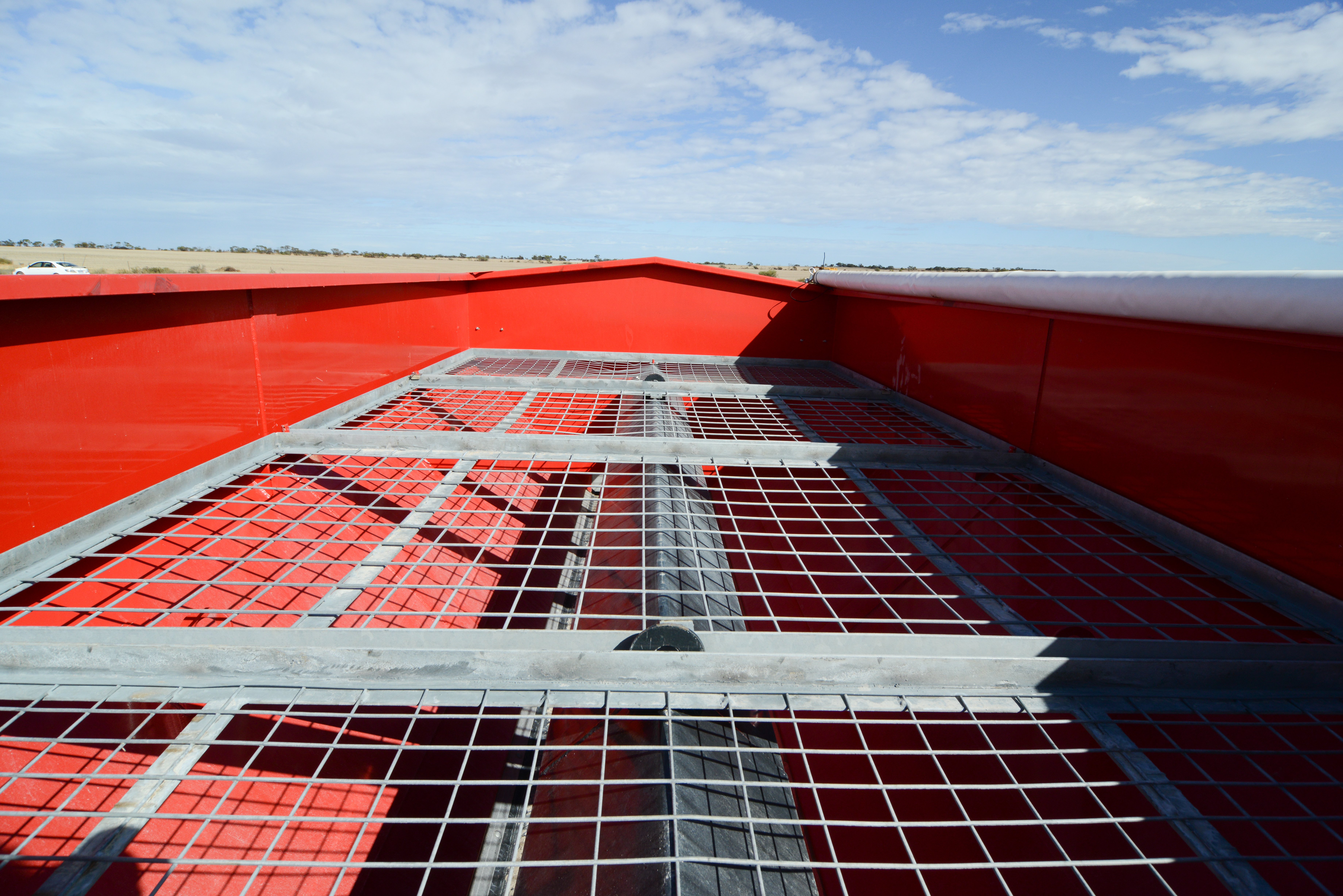

| Hopper Mesh | Yes (25 or 75 mm opt) |

| 3-Speed Gearbox | Standard |

| Rate Controller Type | Land Drive |

| 36m Fertiliser Kit | Yes |

| Variable Rate Ready | No |

| Hydraulic Brakes | Yes |

| Lights | Yes |

| Roll Over Cover | Yes |

| Tachometer | Yes |

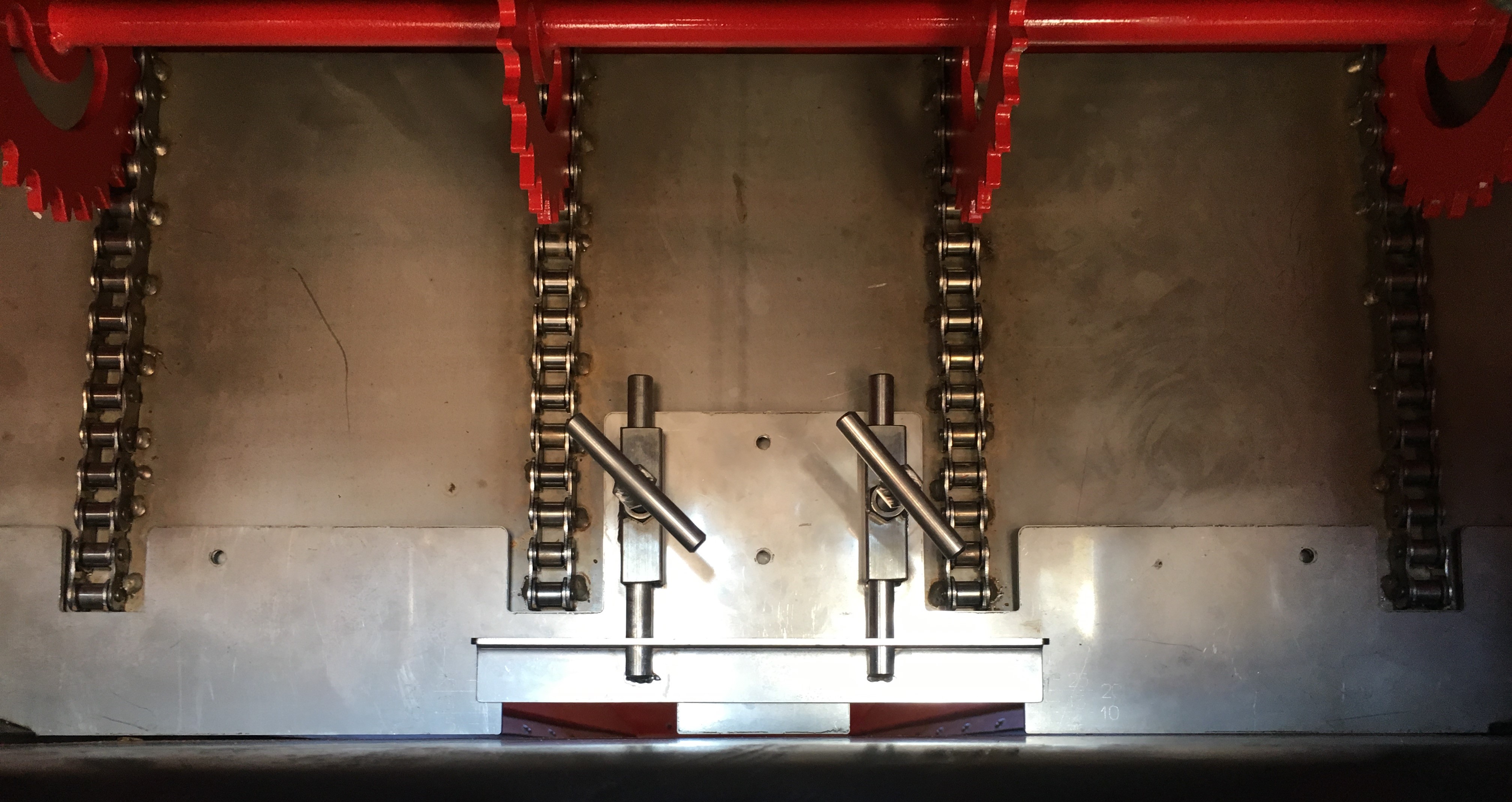

| Feed Plate Adjusters | Yes |

| Chains | Yes |

AS120 Fertiliser, Lime, Gypsum & Manure Spreader | Optional Specifications Table

| MODEL | AS120 |

|---|---|

| Load Cells | Yes |

| In-Cab Border Control | Yes |

| Air Brakes | Yes |

| Hydraulic Drive | Yes |

| Rate Controller | Apollo II |

| Axle Track (All Hyd Drive Only) | 3M |

| Stainless Steel Hopper | Yes |

| Steerable Axle | N/A |

| Tyre Options | Yes |

| TransferTrack | No |

| Hydraulic Folding Curtains | Yes |

- Capacity 10.6m3

- 550/60-22.5BKT Flotation Tyres

- 10 Stud Axle

- 2M Axle Track Width

- Sprung Drawbar

- 36m Fertiliser Discs

- Lime, Manure & Gypsum disks

- 25 or 75 mm option Hopper Screen Mesh

- 3 Speed Gearbox Land Drive

- Hydraulic Brakes

- LED Tail Lights

- Roll Tarp

- Tachometer

- High Spec Calibration & Test kit

- Stainless Steel Fittings

- Plastic Mudguards

- Shot blast & two-pack paint treatment

- Load Cells

- Apollo II - Hyd Drive ISOBUS

- Fethers False Door

- Stainless Steel Bin

- Headland Control

- Hydraulic PTO Pump

- 3m Wheel Centres

- Hydraulic Folding Curtains

Flotation Tyres give a superior ride and minimise footprint. Available in Trelleborg or BKT tyres .

Flotation Tyres give a superior ride and minimise footprint. Available in Trelleborg or BKT tyres . The Sprung Drawbar is designed to dampen shock energy transfer between the tractor and the Agrispread, ensuring a smoother ride and extending the life of the spreader.

The Sprung Drawbar is designed to dampen shock energy transfer between the tractor and the Agrispread, ensuring a smoother ride and extending the life of the spreader. 36m Fertiliser Discs are easily interchangeable with the Lime, Manure and Gypsum Discs to maximise accuracy for different products. Spreads Urea to 36m – Independently certified and farmer proven.

36m Fertiliser Discs are easily interchangeable with the Lime, Manure and Gypsum Discs to maximise accuracy for different products. Spreads Urea to 36m – Independently certified and farmer proven. Easily Manageable Interchangeable Discs allow for a quick and simple change between applications. Maximising accuracy for different products. Spreads Lime & Gypsum up to 16m.

Easily Manageable Interchangeable Discs allow for a quick and simple change between applications. Maximising accuracy for different products. Spreads Lime & Gypsum up to 16m. Hopper Screen Mesh comes standard and keeps large objects away from belts and spinners to maintain a even and precise spread and not cause any damage.

Hopper Screen Mesh comes standard and keeps large objects away from belts and spinners to maintain a even and precise spread and not cause any damage. Hydraulic brakes work with the tractors hydraulic braking system giving you control and safety when under load. The machine can be still operated without this feature.

Hydraulic brakes work with the tractors hydraulic braking system giving you control and safety when under load. The machine can be still operated without this feature. LED Tail lights give indicator safety to the operator and others when transporting or moving machine.

LED Tail lights give indicator safety to the operator and others when transporting or moving machine. Operated from the back of the machine, the sprung roll tarp is designed to provide a weather proof area for product and keeps the hopper clean when not in use.

Operated from the back of the machine, the sprung roll tarp is designed to provide a weather proof area for product and keeps the hopper clean when not in use.

Plastic Mudguards help deflect dust and mud from the outside of the hopper and the rear of the spreader, helping to prevent corrosion. The plastic allows for flex to minimise damage if struck.

Plastic Mudguards help deflect dust and mud from the outside of the hopper and the rear of the spreader, helping to prevent corrosion. The plastic allows for flex to minimise damage if struck. Agrispread spreaders are shot-blasted and finished with a 2 pack commercial grade paint. UV resistant and provides a long lasting and durable surface finish.

Agrispread spreaders are shot-blasted and finished with a 2 pack commercial grade paint. UV resistant and provides a long lasting and durable surface finish. Load Cells give the Spreader ultimate accuracy and allow for continuous calibration of product.

Load Cells give the Spreader ultimate accuracy and allow for continuous calibration of product. ISOBUS compatible, the Apollo II system connects to any ISOBUS compatible tractor. This enables the operator to manage setup, calibration and rate control from the Virtual Terminal Display. VRT compatible.

ISOBUS compatible, the Apollo II system connects to any ISOBUS compatible tractor. This enables the operator to manage setup, calibration and rate control from the Virtual Terminal Display. VRT compatible. Fitted to the existing Spreader door, the false door provides for the application of very low rates of products like Mouse Off ®  Snail baits and small seeds.

Fitted to the existing Spreader door, the false door provides for the application of very low rates of products like Mouse Off ®  Snail baits and small seeds. Optional complete Stainless Steel Bin provides a complete rust protection option for your spreader to minimise maintenance and corrosion increasing the life span of the spreader.

Optional complete Stainless Steel Bin provides a complete rust protection option for your spreader to minimise maintenance and corrosion increasing the life span of the spreader. Headland Control reduces coverage at paddock edges by reducing outside spinner speed. Minimises overthrow on first paddock pass and boundaries.

Headland Control reduces coverage at paddock edges by reducing outside spinner speed. Minimises overthrow on first paddock pass and boundaries. 3m wheel centres are an option to enable the spreader to fit with CTF systems.

3m wheel centres are an option to enable the spreader to fit with CTF systems. Hydraulic Folding Curtains are attached to the rear of the spreader. Completely folding away for transport they increase productivity by allowing low density products to be spread in windy conditions by deflecting the oncoming air over the curtains. Hydraulic Folding Curtains can be retro-fitted.

Hydraulic Folding Curtains are attached to the rear of the spreader. Completely folding away for transport they increase productivity by allowing low density products to be spread in windy conditions by deflecting the oncoming air over the curtains. Hydraulic Folding Curtains can be retro-fitted.